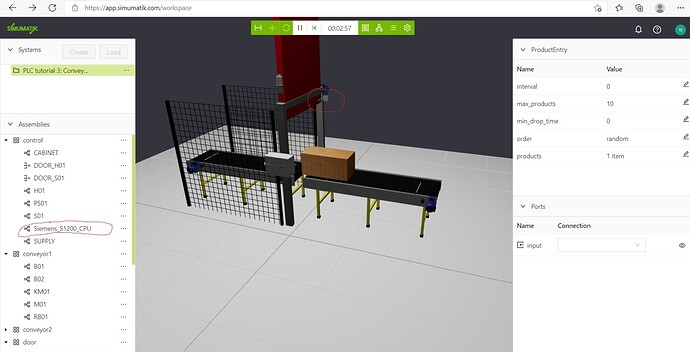

Hello, I am practicing plc tutorial 3: conveyor and door, my program logic is like this: when the door goes up and sensor B05 senses the plate on the door, the door stops moving up, but during the operation, the door continues to go up and crosses the sensing range of the sensor, thus causing the motion logic of the whole system to interrupt here, I tried to lower the z-axis position of the palte attached on the door, so that the system can work as what I want, but I still do not understand why did not work based on the original setting when the inductor sensor B05 has been energized?

As a side note, the same program was executed in codesys without problems, but when using PLCSIM advanced I encountered this problem. I guess it may be a problem of delay, the minimum sampling and publishing interval in PLCSIM advanced has been set at the minimum value of 100ms and 500ms, respectively. This problem happened from time to time, any way, I will try with PLCSIM instead of PLCSIM advanced and see how it works.

Hi, just as you said this is a limitation of PLCSIM advanced. A total delay of 200ms can make it miss the metal plate. We will update the position of the plate in the system. Did you have any success with trying PLCSIM instead?

Hi, Thank you for your reply.

Yes, I have successfully used plcsim and this problem has not happened again.

Also, with my current knowledge, I don’t think it’s the problem of the location of the plate, but simply the latency of different 3rd party software, so keeping it as it is might help the user distinguish the effect of using different 3rd party software, at the same time, it gives me an important insight that the design and assembly of the system needs to be integrated according to the hardware/software used by the user. Thanks again!